Even though they started as large, awkward machines, drum sanders have been the target of technological advances, meaning that, each year, you can get smaller products with twice the power.

We believe that drum sanders are, unjustly, one of the most overlooked tools in a woodworker’s arsenal, so we’re here to tell you everything you need to know about these incredibly powerful, useful and efficient machines.

What Is a Drum Sander?

Now, drum sanders are not for the beginner do-it-yourselfer – unless you’re really dedicated – as they are some badass beasts. In terms of sheer power, you just need to turn them on and listen to their amazing roar to understand how efficiently they can help you tackle some hard and extensive projects.

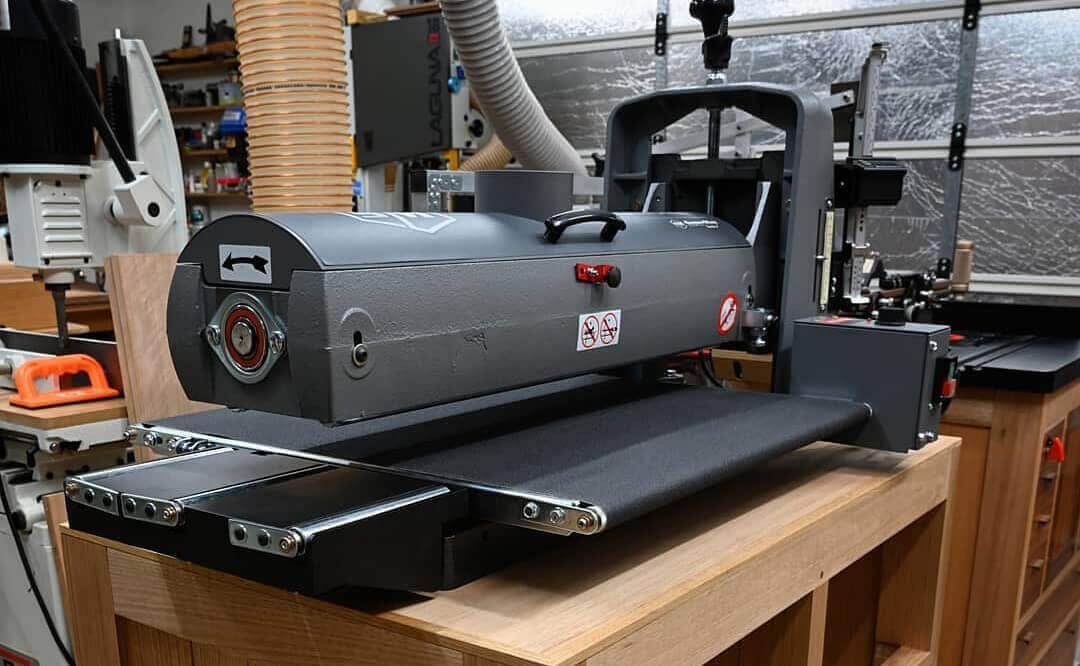

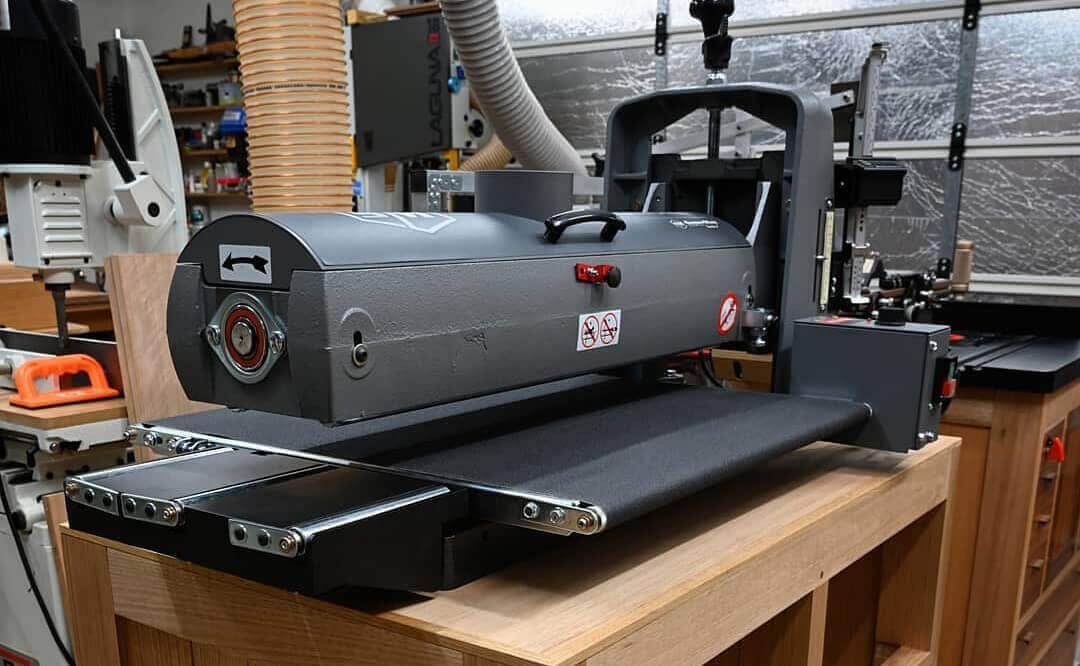

We’re talking about a stationary machine, composed of a drum/spinning cylinder, where you can place your abrasive material, and a conveyor belt, aiding you in feeding the piece to the sander. Some models even have the option to choose different feeding rates on the conveyor belt, meaning you can adjust the process to the type of wood at hand.

On one side, you lose the portability aspect of common handheld tools, even though most drum sanders bring a table to be set on or are hip-high. On the other side, you get a more efficient, effortless and quicker sanding process turning a days’ worth task into an hours’ one. You can check out the best ones on the market, at the moment, right here.

The major aspects you have to decide on, before getting one, is if you want an open (most common one) or closed design and a single (more economic) or dual drum (more efficient).

What Are They Good for?

Drum sanders aren’t the type of machine that you can own as the sole weapon in your woodworking’s arsenal, as there are some finer, complex projects you’re better off with a palm or a detail sander. If we’re talking about sanding long, thick and flat surfaces, like cabinet doors and tables, this sander will offer you an effortless and extremely efficient result. Actually, there are a lot of luthiers (instruments’ craftsmen) that use them for guitars and violins. Now, you might be thinking: “If it was portable, I bet it could take care of wooden floorings in no time, with amazingly polished results.” Well, you’re right! And the best part is that there are a few portable models, specially designed to tackle flat surfaces, like decks and interior floors, leaving them ready for a beautiful coat of varnish.

Tips on How to Use Them

As we mentioned before, this isn’t a tool for the regular fellow who likes some DIY projects here and there. Remember, with great power comes great responsibility! Of course, there are no reasons to feel afraid of them because, if used properly, they cause a lot more good than harm.

Here are some tips regarding their use:

- Before even turning it on, inspect the piece at hand and make sure it doesn’t have any nails or cracks and gaps that need repairing.

- When working a piece, and since the drum motor and the conveyor belt motor are separated, you can turn on only the latter, put your piece on it and lower the drum till it barely touches it. That way, you can get a feel and make sure you won’t remove too much material on the first try.

- Only lower the drum 1/8 to 1/4 turn each time, so you don’t ruin the piece and put too much stress on the machine – some models have digital height readouts that make this process super easy and safe.

- After each process, feed your piece in different directions – it evens out the sanding.

- If you’re using a portable floor model, go along the length of the floorboard and keep moving at all times – if you stop in one place, you can easily damage your floor. Also, when turning it on and off, slightly tilt the machine.

- The coarseness of the sandpaper depends on the type of wood and the result you wish to achieve, but a good rule of thumb is to always start with more coarse sandpaper (smaller grit value) and work your way to a finer one (lower grit value).

- Dust masks, eye and ear protection and a ventilated room are strongly suggested!

- If it starts to feel hot (it will, probably after a good half hour of use) let it cool down for a few minutes.

Final Thoughts

Drum sanders deserve more attention from the world of woodworkers, as they can turn an arduous and painfully boring project into a fun and effortless one. But, due to its power and efficiency, always remember – respect the tool! Thanks for reading and be sure to leave your thoughts on drum sanders in the comments section below.